|

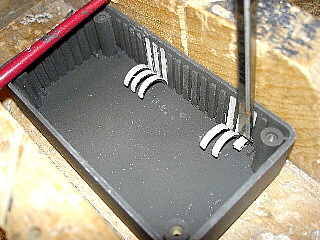

The enclosure is an ABS box with a RFI internal coating

coating (RS part number 501-553). The box has internal ribs, some of

which may need to be removed using a narrow chisle. First remove two centre

ribs at the rear for the headphone socket. |

|

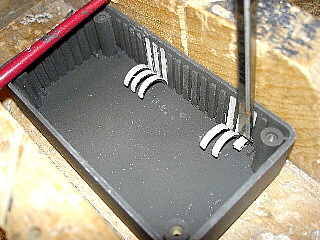

Ribs will need to be removed for the control pots if their

body depth is greater than 8mm. ( photo shows |

|

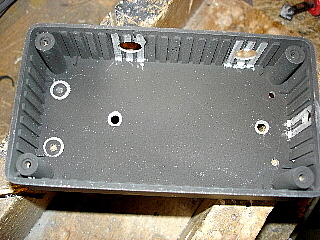

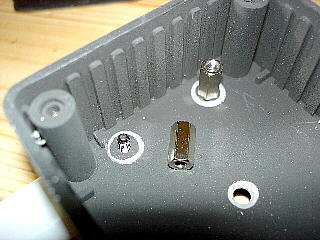

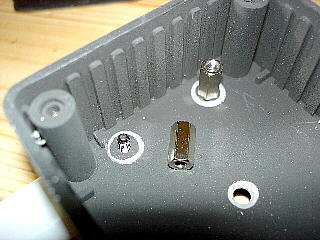

Drill two 2mm holes for the driven element, Then remove the

RFI coating to create an isolated pad. |

|

Hand drill, using a 9mm diameter wood drill, to create the pads. If a new

drill is used, blunt the pointed ends with a file to produce a wide

groove around the pads. |

|

Enlarge the holes to 3mm after creating the pads. |

|

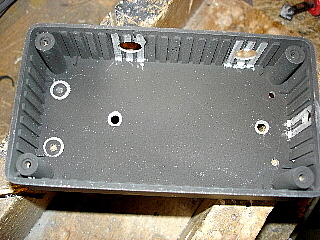

The finished box with all holes drilled. |

|

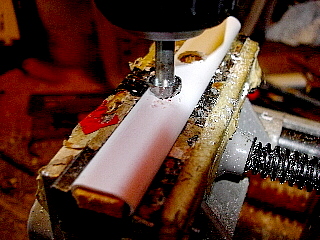

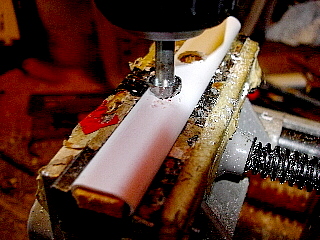

A yoke carrying the driven element is made from 16mm wide

oval plastic conduit, 100mm long. Drill two 3mm holes at 25mm spacing

on both sides. |

|

Open out two holes on one side to 8mm diameter (min). Try

using a countersink drill. A regular drill will often rip the plastic,

unless it is very blunt. |

|

Use 3mm diameter - 10mm spacers inside the box to support the

pcb. Use 8mm male/female spacer on the ouside to provide the connection

to the driven elements. |

|

Underside of the box showing the yoke peice and pipe clips

fixed. Note the pipe clips will just snap over the boom with the

projecting bolts located in holes in the boom. A half-height 4mm nut is

used to secure the pipe clip to the ABS box |